METAL SUB-GIRT FABRICATION & SUPPLY

Metal sub-girts supplied with fast turnaround and reliable delivery.

Standard Sub-girts

J-Bar

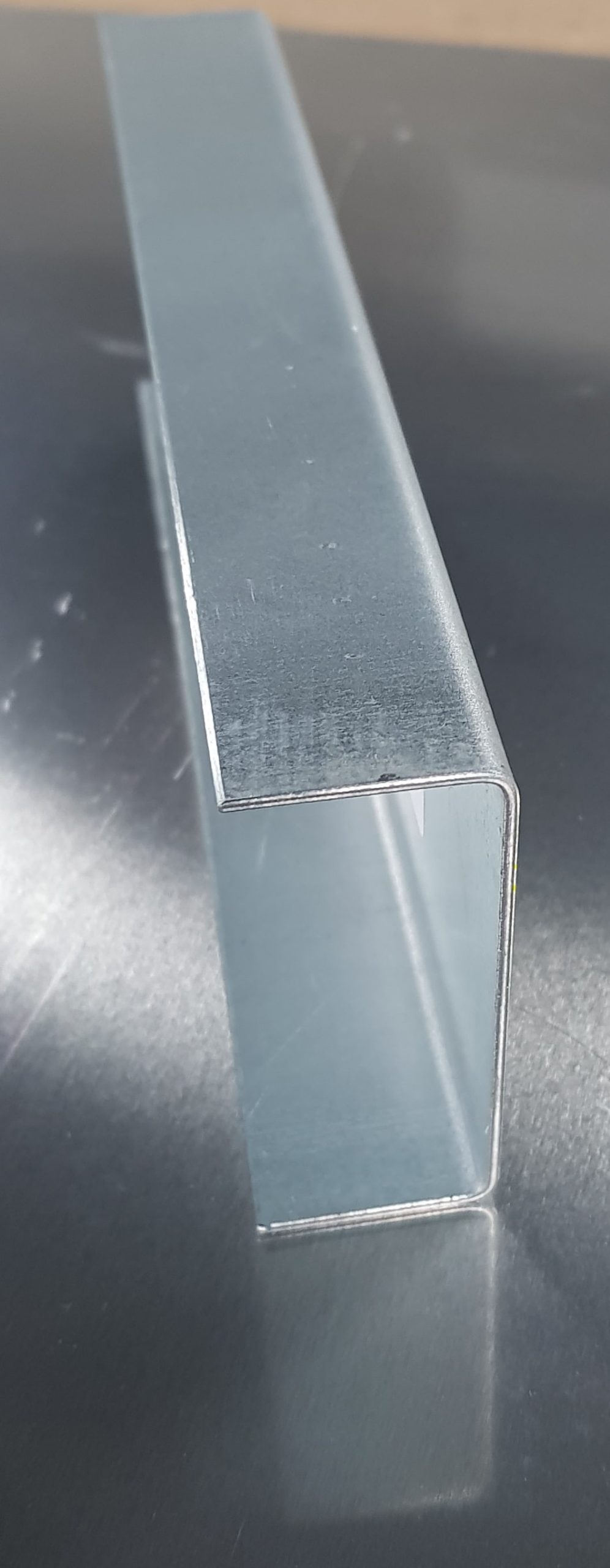

U-Bar

C-Section

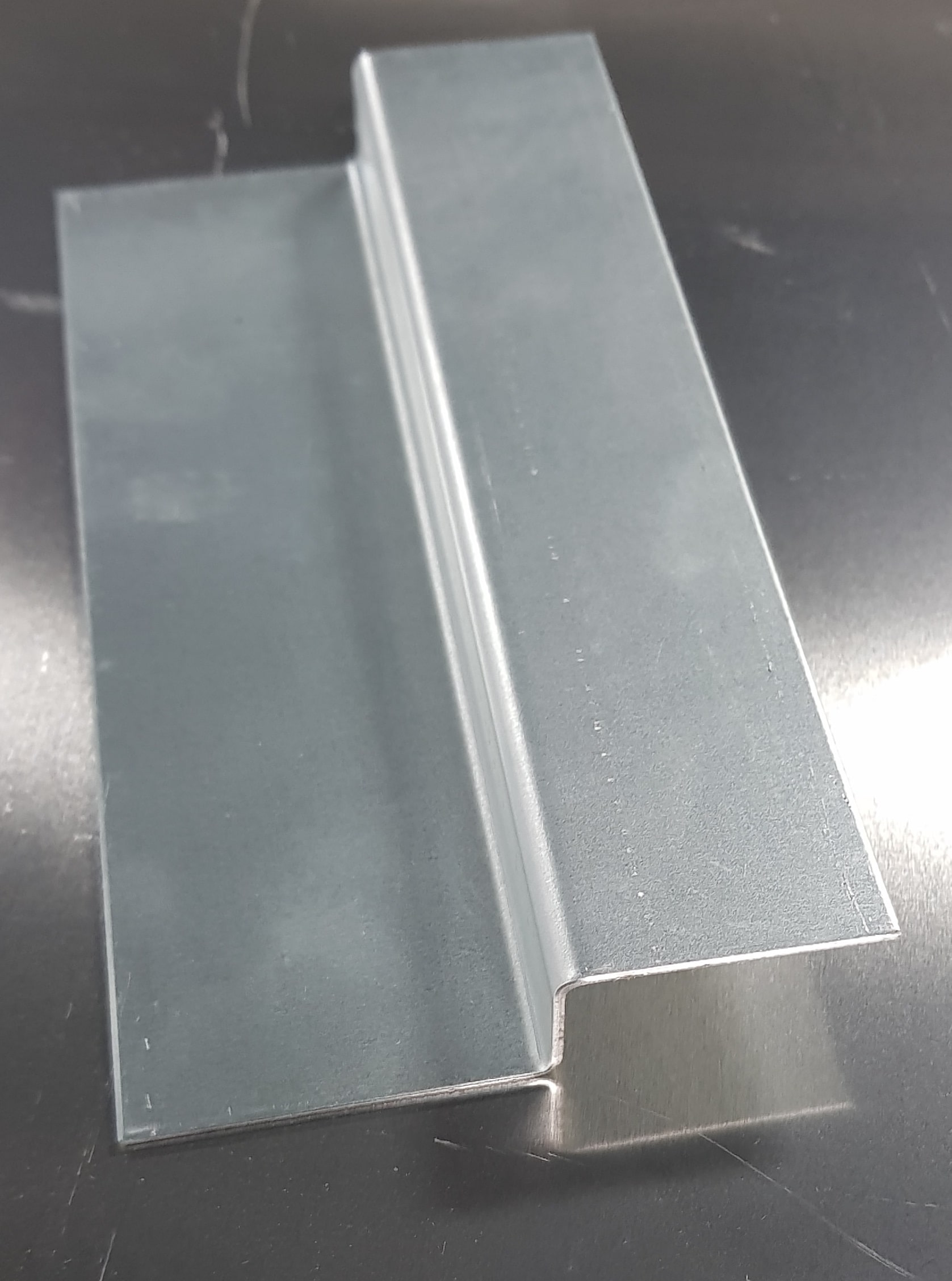

Z-Purlin

Z-Bar

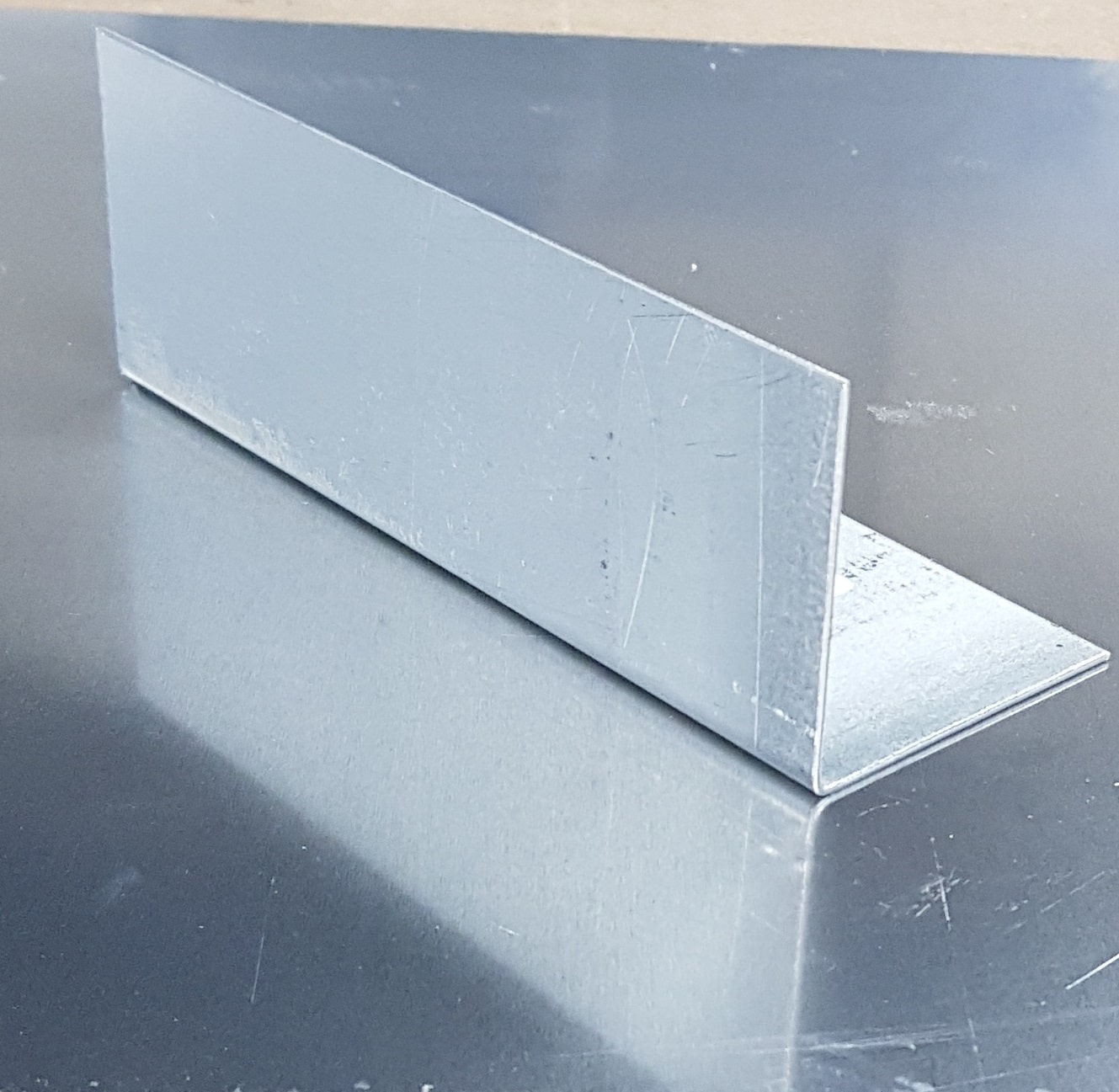

L-Bar / Angle

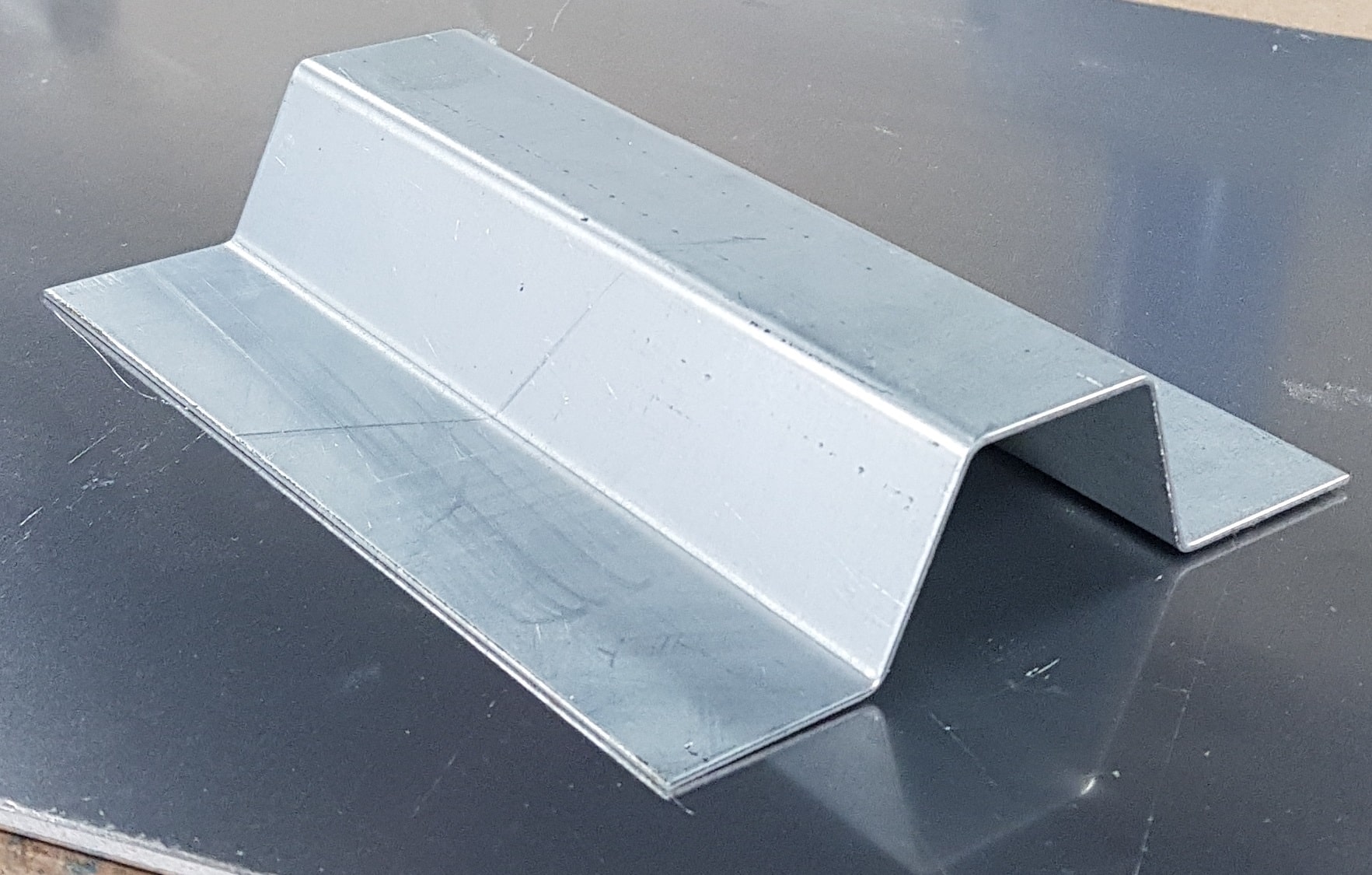

Hat Channel

Vented Hat Channel

Other cold-formed sub-structural components available on request.

Sub-Girt Materials & Fabrication Capabilities

We fabricate metal sub-girts with a range of material, gauge, and fabrication options to support exterior cladding systems in Toronto, the GTA, and across Ontario.

Material & Gauge Options

11 to 24 Gauge Galvanized Steel

Heavy and light gauges available with corrosion-resistant zinc coating

Aluminum

Lightweight, corrosion-resistant option commonly used in exterior framing

Stainless Steel

For high-corrosion environments or special applications

Painted or Coated Steel

Available when a finish color or protective coating is specified

Standard Profiles

We can fabricate common framing shapes that match cladding support requirements.

Advanced Fabrication Capabilities

These capabilities help save field time and simplify installation.

Punching and Notching

Holes and cutouts per drawing or field layout

Flat Straps

For bracing and attachment needs

Custom Notched Bars

Profile notches matched to specific cladding or roofing profiles

Custom Lengths

Sub-girts made to your required dimensions, up to custom length limits

Finish & Protection

Metal Sub-Girt Fabrication Capabilities

Specification Table

| Category | Options / Details | Why It Matters |

|---|---|---|

| Material Types | Galvanized steel | Most common, corrosion-resistant for exterior use |

| Aluminum | Lightweight and corrosion-resistant option | |

| Stainless steel | For high corrosion environments or wash-down areas | |

| Painted / coated steel | Color or finish per project requirement | |

| Standard Profiles | Z-Bars | Basic support for panel systems |

| C-Channels | Common support profile | |

| Hat channels | Provides level backing for panels | |

| L-Angles | For edges, transitions, detail work | |

| Fabrication Features | Punching & Notching | Holes/slots per drawings for fasteners |

| Flat Straps | Bracing and connection straps | |

| Custom Notched Bars | Sub-girts notched to fit specific profiles | |

| Custom Lengths | Cut to size for each project run | |

| Finish & Packaging | Galvanized coating | Rust protection |

| Painted / coated finish | Meets architectural finish specs | |

| Labelled & packed | Easy sorting and staging on site | |

| Typical Uses | ACM panel support | Backing for composite cladding |

| Metal panel cladding | Used with rainscreen and facade systems | |

| Cassette panel systems | Provides stable framing for panels | |

| Retrofit & new cladding | For modern exterior facades |

Get Pricing for Metal Sub-Girts

Need sub-girts for your cladding project? Reach out for pricing, lead times, and fabrication options.